NiAl cladding foda tare da ƙarfi haɗin gwiwa

Bayani

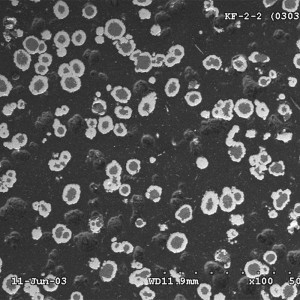

Muna alfaharin gabatar da samfurori guda biyu dangane da NiAl foda: KF-2 da KF-6.Wadannan samfurori guda biyu suna amfani da nau'i daban-daban na NiAl foda kuma suna da halaye na musamman da aikace-aikace.

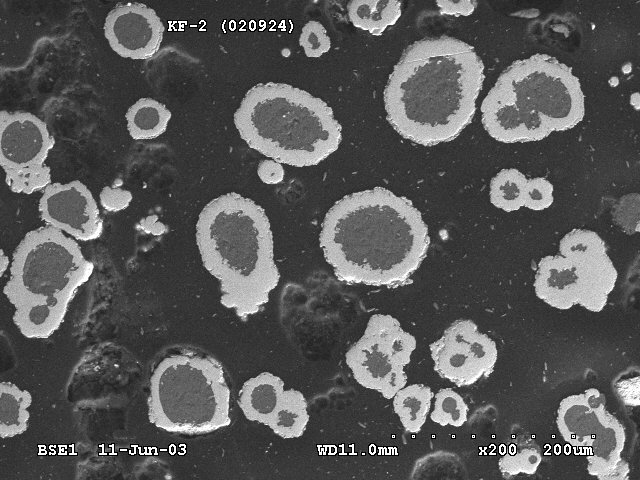

KF-2 yana amfani da NiAl82/18, wanda ya ƙunshi 82% Ni da 18% Al.Wannan samfurin ya dace da aikace-aikace tare da matsakaicin zafin aiki na 650°C.Yana bayar da wani m, machinable, hadawan abu da iskar shaka-resistant, kuma lalacewa-resistant shafi tare da kai bonding Properties.Koyaushe akwai halayen exothermic yayin aikin fesa, wanda ke haifar da kyakkyawan ƙarfin haɗin gwiwa sama da kayan Ni5Al.KF-2 ya dace da gyare-gyare da sake ƙera machin carbon karfe da ƙarfe mai jurewa, kuma ana iya amfani da shi don haɗa yadudduka na yumbu da kayan sawa.

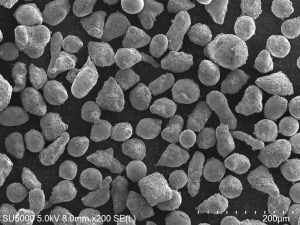

KF-6 yana amfani da NiAl95/5, wanda ya ƙunshi 95% Ni da 5% Al.Wannan samfurin ya dace da aikace-aikace tare da matsakaicin zafin aiki na 800 ° C kuma ana iya amfani dashi ta amfani da hanyoyi daban-daban na fesa kamar harshen wuta, APS, da HVOF.Har ila yau yana ba da wani abu mai yawa, mashinable, oxidation-resistant, da lalacewa mai jurewa tare da abubuwan haɗin kai.Akwai ko da yaushe wani exothermic dauki a lokacin spraying tsari, haifar da kyakkyawan bonding ƙarfi.Hakanan za'a iya amfani da KF-6 don gyarawa da sake yin masana'anta na carbon karfe da ƙarfe mai jure lalata, da kuma haɗa yadudduka na yumbu da kayan sawa.

A taƙaice, duka KF-2 da KF-6 sune samfuran tushen foda na NiAl waɗanda ke ba da ƙarfin haɗin gwiwa mai kyau da juriya.KF-2, wanda ya ƙunshi ƙananan adadin NiAl foda (NiAl82 / 18), ya dace da aikace-aikace tare da matsakaicin zafin jiki na aiki na 650 ° C, yayin da KF-6, tare da mafi girma na NiAl foda (NiAl95/5), zai iya ɗaukar yanayin zafi mai girma har zuwa 800 ° C kuma ana iya amfani dashi ta amfani da hanyoyin feshi daban-daban.Dukansu samfuran suna da kyau don gyarawa da sake ƙera mashin ƙarfe carbon ƙarfe da ƙarfe mai jure lalata, da kuma haɗa nau'ikan yumbu da kayan sawa.Zaɓin tsakanin KF-2 da KF-6 ya dogara da ƙayyadaddun buƙatun aikace-aikacen da matsakaicin zafin aiki da ake buƙata.

Makamantan samfuran

| Alamar | Sunan samfur | AMPERIT | METCO/AMDRY | WOKA | PRAXAIR | PAC |

| KF-2 | NiAl82/18 | 404NS | ||||

| KF-6 | NiAl95/5 | 282 | Farashin 956450 | NI-109 | 906 |

Ƙayyadaddun bayanai

| Alamar | Sunan samfur | Chemistry (wt%) | Tauri | Zazzabi | Kayayyaki & Aikace-aikace | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Al | W | Mo | Cr | Farashin 2O3 | MoS2 | WC | C | Fe | Ni | |||||

| KF-2 | NiAl82/18 | 20 | Bal. | Farashin HRC20 | ≤800ºC | • Wuta, APS, Max.zafin aiki 650°C. • m da machinable hadawan abu da iskar shaka resistant da sa resistant shafi. | ||||||||

| KF-6 | NiAl95/5 | 5 | Bal. | Farashin HRC20 | ≤800ºC | • Harshen wuta, APS, HVOF, Max.zafin aiki 800 ° C • m da machinable hadawan abu da iskar shaka resistant da sa resistant shafi | ||||||||

| KF-20 | Ni-MoS₂ | 22 | Bal. | Farashin HRC20 | ≤ 500ºC | •Ana amfani da shi don sassauƙan hatimi mai motsi da zoben rufewa • Ana iya amfani da shi azaman ƙananan juzu'i | ||||||||

| KF-21T | Ni-Graphite 75/25 | 25 | Bal. | Farashin HRC20 | ≤480ºC | • harshen wuta, Max.aiki zafin jiki 480 ° C 1. Saka kayan na turbo compressor •Masu amfani da nickel gami da sassan karfe • Abubuwan da ke da babban abun ciki na graphite sun dace da sassan titanium ba tare da gefen ba Babban abun ciki na graphite zai haɓaka aikin sa mai • Babban abun ciki na nickel zai inganta juriya na yashwa • Irin waɗannan samfuran sun bambanta saboda ƙayyadaddun OEM daban-daban | ||||||||

| KF-22T/R | Ni-Graphite 60/40 | 50 | Bal. | Farashin HRC20 | ≤480ºC | |||||||||

| KF-21R | Ni-Graphite 75/25 | 25 | Bal. | Farashin HRC20 | ≤480ºC | |||||||||

| KF-45 | Ni-Al2O3 77/23 | 23 | Bal. | Farashin HRC40 | ≤800ºC | • Flame, APS, rashin daidaituwa • Ana iya amfani da shi don narkewa crucible, m sealing surface da mold surface a matsayin m Layer | ||||||||

| KF-56 | Ni-WC 16/84 | Bal. | 12 | Farashin HRC62 | ≤400ºC | • Flame, APS, rashin daidaituwa • Juriya ga guduma, yazawa, abrasion da zamewa abrasion | ||||||||

| KF-50 | Ni-WC10/90 | Bal. | 10 | Farashin HRC62 | ≤400ºC | • Wuta, rashin daidaituwa • Juriya ga guduma, yazawa, abrasion da zamewa abrasion | ||||||||

| KF-91F | Fe-WC | 4 | 27 | 9.5 | Bal. | 5.5 | Farashin HRC40 | ≤ 550ºC | • Flame, APS, rashin bin ka'ida, Max.zafin aiki 815°C. •Wear resistant kayan shafa, wanda za a iya amfani da shi domin tanki birki kushin gyara | |||||

| KF-110 | NiCr-Al 95/5 | 5 | 7.5 | Bal. | Farashin HRC20 | ≤800ºC | • Wuta, APS, Max.zafin aiki 980°C. •Fashin filasta tare da haɗa kai | |||||||

| KF-113A | NiCrAl-CoY2O3 | Cr+Al:20, Ni+Co:75 | Farashin HRC20 | ≤900ºC | • APS,HVOF, rashin daidaituwa, Max.zafin aiki 980°C. • Yana da amfani ga gyaran Layer haɗin gwiwa mai zafi ko lalacewa / sassan da ba daidai ba | |||||||||

| KF-133 | NiMoAl | 5 | 5 | Bal. | Farashin HRC20 | ≤ 650ºC | • Haɗin kai, shafi mai wuya gama gari don aikace-aikacen ɗaukar nauyi • Tauri, tare da kyakkyawan juriya na lalata da tasirin tasiri •Ana amfani da sassa na inji, wurin zama da bawul | |||||||

| KF-31 | Ni-Diatomite 75/25 | • Flame, APS, wanda bai bi ka'ida ba, Max.zafin aiki 650°C. • Domin grindable hatimi shafi, ciki har da m hatimi sassa, grindable hatimi zobba, low gogayya kayan | ||||||||||||